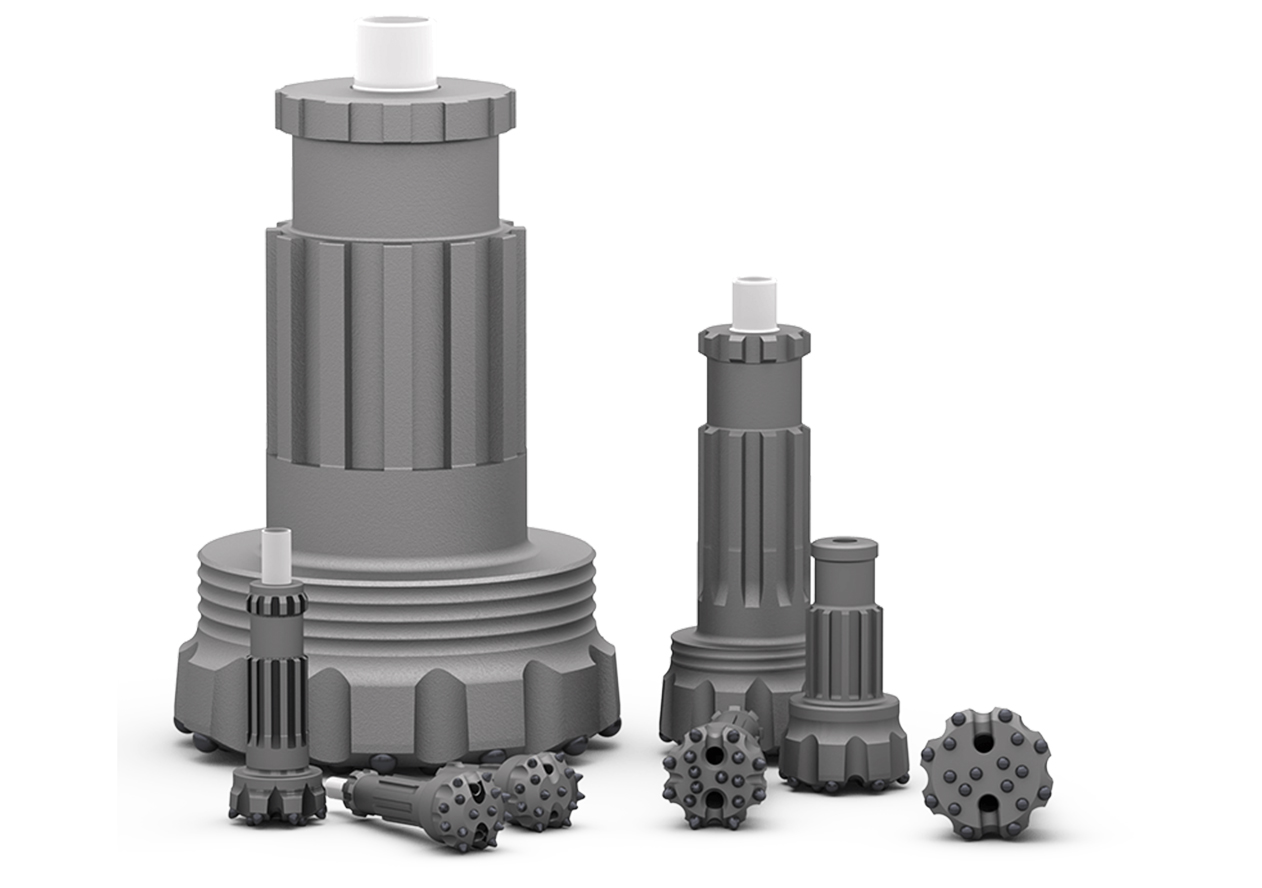

Mincon MR120-LA RC Hammer (4 1/2″ Metzke)

The MR range of RC hammers is designed to perform at the top end of the performance scale compared to other tools on the market. With extensive testing over an 18 months period the MR range of tools offers some very significant benefits over it’s predecessor, the MX range of RC hammers.

Performance improvements show up to 20% increase in production in both grade control and exploration applications vs. the Mincon MX range. As with all Mincon hammers the tools performed extremely well in deep hole drilling in dry applications and where there is a lot of water in the bore hole. With a variable length available on the chuck sleeve the hammer can be easily set up for either dry or wet hole drilling. Set to become the standard by which RC hammers will be measured, the Mincon MR range of tools get the job done.

Key Features and Benefits

- Patented mounting system for fixed internal components.

- An extremely sturdy shank with a short length allows for greater transfer of energy between the piston and bit.

- Variable chuck sleeve lengths for varying drilling conditions.

- Single piece sample tube assembly.

- Specially heat treated sample tubes offer superior wear resistance vs. our competitors.

- Variable sample tube bore sizes allows the contractor greater flexibility in setting up his tool.

- Hardened wear sleeve for optimum wear resistance even in the most abrasive conditions.

- Multi-start threads on backhead and chuck ensure easy coupling/uncoupling of hammer.

- Metal sprayed chuck sleeve and wear sleeve options for greater wear resistance on outside circulation.

- All critical internal components are heat treated under strict control to maximize tool longevity.

- Ease of service with no special assembly or disassembly tools required.

For more information:

+40 314 253 800

info@romned.ro

Ron van Dam

CEO

| Specifications | Metric | Imperial |

| Hammer Outside Diameter | 120mm | 4.75″ |

| Hammer Length (Less Drill Bit) | 1165mm | 45.9″ |

| Backhead Spanner Flat Size | 94mm | 4″ |

| Drill Bit Shank Type | MR120 | |

| Backhead Thread | 4 1/2″ Metzke | |

| Drill Bit Size Range | 127mm – 143mm | 5″ – 5.625″ |

| Hammer Weight (Less Bit) | 70 Kgs | 154 Lbs |

| Maximum Drill Bit Weight | 14.5 Kgs | 32 Lbs |

| Piston Weight | 16 Kgs | 35.3 Lbs |

| Make up Torque | 4826-6440 NM | 3560-4750 FT Lbs |

| Backhead Stand Off | 0.75mm | 0.030″ |

| Recommended Minimum Air Package | 25.5m3/min @ 24.1Bar | 900cfm @ 350psi |

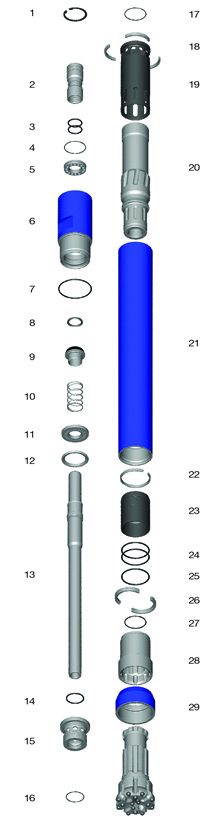

| Item | Part No | Description |

| MR120AL04 | MR120 Hammer 4 1/2″ Metzke – Low Air | |

| 1 | 1300-0780 | Internal Circlip |

| 2 | MX5053AT31 | Adaptor Tube 4 ½ Metzke |

| 3 | BS-224 | O Ring x 2 |

| 4 | BS-040 | O Ring |

| 5 | MX5053SC01 | Air Screen |

| 6 | MR120BH31 | Back Head 4 ½” Metzke |

| 7 | BS-241 | O Ring |

| 8 | 8406-175 | Check Valve Seal – Nitrile U |

| 9 | MR120CV01 | Check Valve Plunger |

| 10 | MR120SP01 | Check Valve Spring |

| 11 | MR120SS01 | Spacer |

| 12 | MX4550LR01 | Lock Ring |

| 13 | MR120ST01 | Sample Tube – Large Bore |

| MR120ST03 | Sample Tube – Small bore | |

| 14 | BS 228 | O Ring |

| 15 | MR120DR02 | Sample Tube Mount |

| 16 | BS 234 | O Ring |

| 17 | BS 040 | O Ring |

| 18 | MX5053SR01 | Seating Ring |

| 19 | MR120IC01 | Inner Cylinder |

| 20 | MR120PN01 | Piston |

| 21 | MR120WS01 | Wear Sleeve |

| 22 | MX5053PR01 | Piston Retaining Ring |

| 23 | MR120BB01 | Aligner Bearing Bush |

| 24 | N7-92×4 | O Ring x 2 |

| 25 | BS 237 | O Ring |

| 26 | MR120BR01 | Bit Ring |

| 27 | BS 152 | O Ring |

| 28 | MR120CK01 | Chuck |

| 29 | MR120CSxxxLMR120CSxxxL | Chuck Sleeve |

| MR120OKIT | O Ring Kit | |

| MR120MK01 | Make up kit |

Air Pressures are given for compressors operating at seal level at 20° C (68º F). Corrections to actual compressor volume should be made to account for temperature, altitude and relative humidity.

Air Pressures are given for compressors operating at seal level at 20° C (68º F). Corrections to actual compressor volume should be made to account for temperature, altitude and relative humidity.

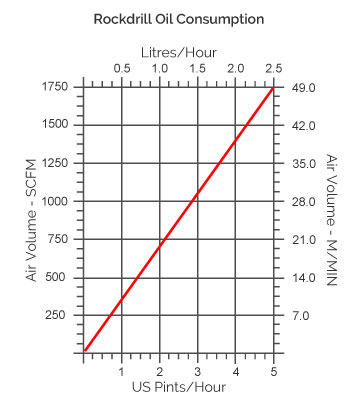

DTH hammers must receive a constant supply of proper rock drill oil to protect the internal components and to provide a good air seal between the hammer’s running surfaces for efficient drilling. Mincon recommends the use of Mincon Envirosafe® Rock Drill Oil (RDO) to maintain optimal performance and extend the life of the internal components. The correct consumption of oil is dependent upon the air volume and conditions. Please refer to the lubrication graph below for recommendations. When drilling in wet conditions the normal amount should be doubled. There should be visual evidence of oil around the drill bit shank and within the tube joints when changing tubes.

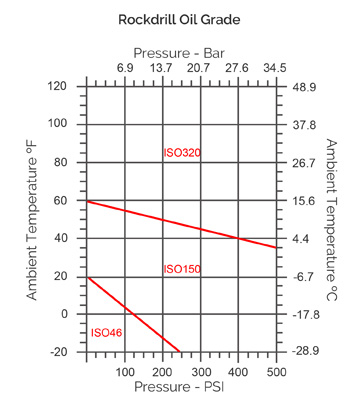

If using petroleum based rock drill oils, the recommended grade of oil is dependent on the ambient temperature and the operating pressure. As a rule of thumb, ISO320 grade rock drill oil should be used whenever possible as the hammer is a high frequency tool, however, where the pump cannot pump the oil in colder conditions, a lower grade of oil can be used as per the graph below.

| Diameter | Face Type | Part Number | Description | No. x Button Dia (inch) | Sample holes | Weight Approx. | ||||

| mm | inch | Outer | Face | Centre | Kgs. | Lbs. | ||||

| 127 | 5 | Drop Centre | 5120127D1 | MR120 5″ DC BIT | 8 * 5/8 | 4 * 9/16 | 3 * 1/2 | 2 | 15 | 33.1 |

| 127 | 5 | Hard Formation | 5120127H1 | MR120 5″ HF BIT | 8 * 5/8 | 6 * 9/16 | 3 * 1/2 | 2 | 15 | 33.1 |

| 130 | 5 1/8 | Concave | 5120130C1 | MR120 5 1/8 CC BIT | 8 * 5/8 | 4 * 9/16 | 4 * 1/2 | 2 | 15 | 33.1 |

| 130 | 5 1/8 | Drop Centre | 5120130D2 | MR120 5 1/8 DEEP DC BIT | 8 * 5/8 | 4 * 9/16 | 3 * 1/2 | 2 | 15 | 33.1 |

| 130 | 5 1/8 | Hard Formation | 5120130H1 | MR120 5 1/8 HF BIT | 8 * 5/8 | 6 * 9/16 | 3 * 1/2 | 2 | 15 | 33.1 |

| 133 | 5 1/4 | Concave | 5120133C1 | MR120 5 1/4 CC BIT | 8 * 5/8 | 4 * 5/8 | 4 * 1/2 | 2 | 15 | 33.1 |

| 133 | 5 1/4 | Drop Centre | 5120133D2 | MR120 5 1/4 DEEP DC BIT | 8 * 5/8 | 4 * 9/16 | 3 * 1/2 | 2 | 15 | 33.1 |

| 133 | 5 1/4 | Hard Formation | 5120133H1 | MR120 5 1/4 HF BIT | 8 * 5/8 | 6 * 9/16 | 4 * 1/2 | 2 | 15 | 33.1 |

| 137 | 5 3/8 | Concave | 5120137C1 | MR120 5 3/8 CC BIT | 8 * 5/8 | 4 * 5/8 | 4 * 1/2 | 2 | 15 | 33.1 |

| 137 | 5 3/8 | Drop Centre | 5120137D2 | MR120 5 3/8 DEEP DC BIT | 8 * 5/8 | 4 * 5/8 | 3 * 1/2 | 2 | 15 | 33.1 |

| 137 | 5 3/8 | Hard Formation | 5120137H1 | MR120 5 3/8 HF BIT | 8 * 5/8 | 6 * 5/8 | 3 * 1/2 | 2 | 15 | 33.1 |

| 140 | 5 1/2 | Concave | 5120140C1 | MR120 5 1/2 CC BIT | 8 * 5/8 | 4 * 5/8 | 4 * 1/2 | 2 | 15 | 33.1 |

| 140 | 5 1/2 | Drop Centre | 5120140D2 | MR120 5 1/2 DEEP DC BIT | 8 * 5/8 | 4 * 5/8 | 3 * 1/2 | 2 | 15 | 33.1 |

| 140 | 5 1/2 | Hard Formation | 5120140H1 | MR120 5 1/2 HF BIT | 8 * 5/8 | 6 * 5/8 | 4 * 1/2 | 2 | 15 | 33.1 |

| 143 | 5 5/8 | Drop Centre | 5120143D2 | MR120 5 5/8 DEEP DC BIT | 8 * 5/8 | 4 * 5/8 | 3 * 1/2 | 2 | 15 | 33.1 |

| 143 | 5 5/8 | Hard Formation | 5120143H1 | MR120 5 5/8 HF BIT | 8 * 5/8 | 6 * 5/8 | 4 * 1/2 | 2 | 15 | 33.1 |

| 152 | 6 | Drop Centre | 5120152C1 | MR120 6″ COLLARING BIT | 8 * 5/8 | 6 * 9/16 | 4 * 1/2 | 2 | 16 | 35.3 |

| 165 | 6 1/2 | Drop Centre | 5120165C1 | MR120 6 1/2 COLLARING BIT | 8 * 5/8 | 8 * 9/16 | 4 * 9/16 | 2 | 18 | 39.7 |

| 190 | 7 1/2 | Drop Centre | 5120190C1 | MR120 7 1/2 COLLARING BIT | 8 * 5/8 | 12 * 5/8 | 4 * 6/16 | 2 | 21 | 46.3 |