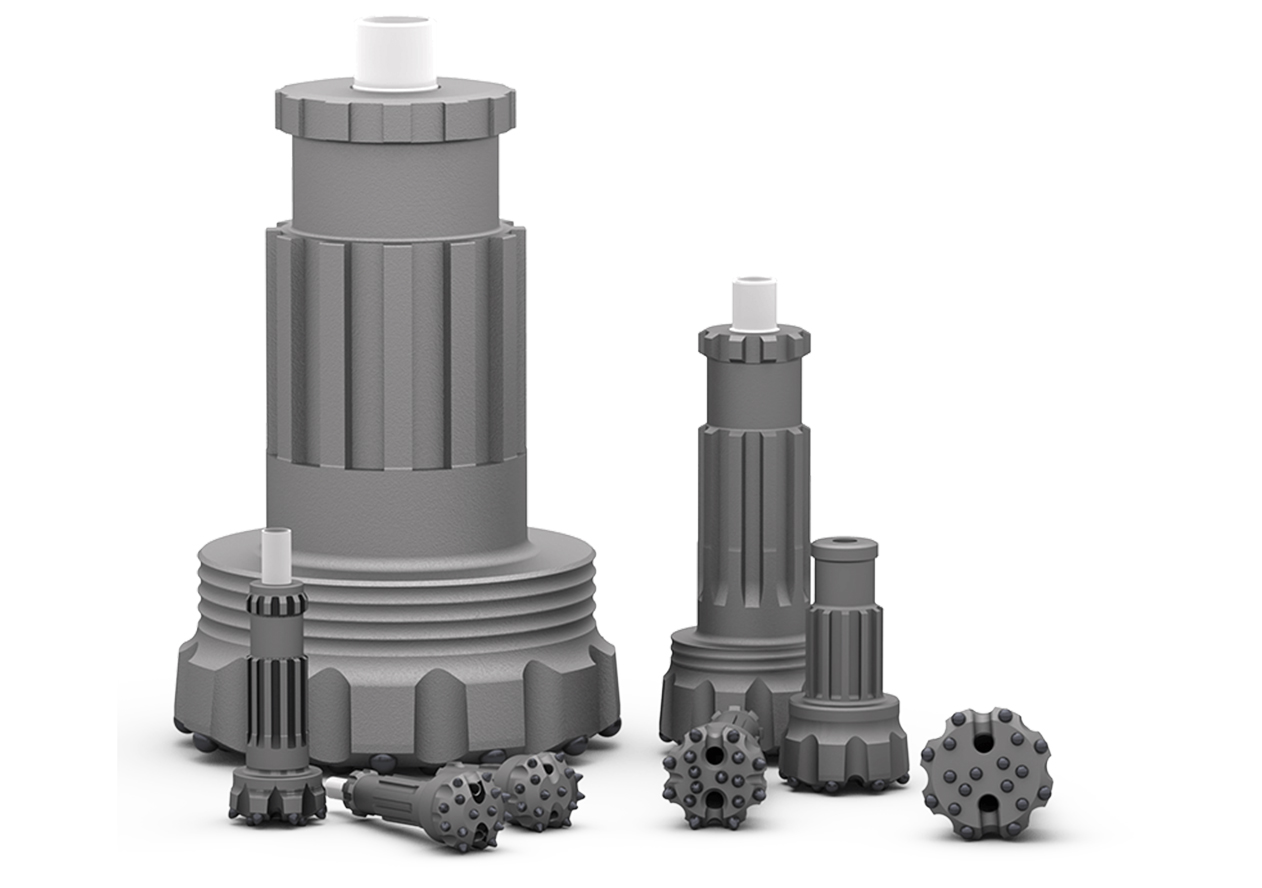

Rotary Drill Bits

Mincon is the only design and manufacturing company in Canada, fully dedicated to Rotary Blast Hole Drill Bits, Drill Pipe, and other string components. “Innovation and Performance” are the foundation of our efforts to produce rugged, dependable, quality products, providing optimal drilling performance for our customers. Our ability and willingness to work directly with our customers to generate customized solutions for their tough and varied drilling conditions is our competitive advantage in the open pit segment of the mining industry.

Features

Mincon Advanced Performance (AP) rotary drill bits are manufactured using aircraft quality steel and premium carbide grades developed to suit the toughest application. Computerized designs using solid modeling, computerized manufacturing processes using the latest in CNC equipment and computer process controlled heat treatment ensure consistent, high quality, drill bits.

Mincon field staff work directly with our customers to test, report, and analyze, critical performance criteria for each drilling condition. Using this data in cooperation with feedback from the driller and operations management, Mincon Rotacan engineering provides a level of customization unique in the industry. Mincon Rotacan recognizes, as all drillers do, that all rock is not created equal.

Design parameters affecting bit life and penetration rates include the Cone Profile wherein the Diameter, Quantity, Geometry, Extension, Spacing, and Grade, of premium grade tungsten carbide inserts are utilized to break the rock. The variables noted are collectively referred to as the bit Cutting Structure.

A tailor made cutting structure provides our customer with the best combination of bit life and rate of penetration to yield the lowest cost per meter. In very harsh or abrasive conditions additional protection is offered by applying Hard Facing alloy material to reinforce critical wear areas of the bit. The cone surface directly behind the gauge row will have one or two rows of Carbide Gauge Inserts to prevent early erosion of the steel.

To prevent dirt and water contamination of the bearings in wet drilling conditions, an optional Backflow Valve is installed. To ensure efficient removal of the rock cuttings Nozzles are properly sized to direct adequate air to lift the cuttings out of the hole while supplying sufficient air through the Bearings and Cones to keep them cool and prevent debris from contaminating the critical bearing area.

For more information:

+40 314 253 800

info@romned.ro

Ron van Dam

CEO

| Item # | Description | |

| 1 | Carbide Inserts | |

| 2 | Ball Bearing | |

| 3 | Main Roller | |

| 4 | End Roller | |

| 5 | Ball Plug | |

| 6 | Protective insert | |

| 7 | Shirt Tail Protection | |

| 8 | Air Passage | |

| 9 | Water Separator | |

| 10 | Air Jet Nozzle | |

| 11 | Backflow Valve | |

| 12 | Threaded Pin Connection |

| Size | UCS | Weight | Weight on Bit | |||||||||

| Inch | mm | AP Series | IADC | Pin Conn. | PSI | Mpa | RPM | Lbs | Kgs | Lbs | Kgs | Ref. Number |

| 9 | 228 | AP4 | 4.3.2 | 6 5/8″ API | 2,000-18,000 | 13.8-124.1 | 50-140 | 104 | 47.2 | 9000-45000 | 4086-20430 | 09000-4-000 |

| 9 | 228 | AP5 | 5.3.2 | 6 5/8″ API | 8,000 – 30,000 | 55.2-206.8 | 50-120 | 104 | 47.2 | 27000-54000 | 12258-24516 | 09000-5-000 |

| 9 | 228 | AP6 | 6.3.2 | 6 5/8″ API | 15,000 – 44,200 | 103.4-304.7 | 50-110 | 104 | 47.2 | 36000-63000 | 16344-28602 | 09000-6-000 |

| 9 | 228 | AP7 | 7.3.2 | 6 5/8″ API | 30,000 – 60,000 | 206.8-413.7 | 50-100 | 104 | 47.2 | 45000-72000 | 20430-32688 | 09000-7-000 |

| 9 7/8 | 250 | AP4 | 4.3.2 | 6 5/8″ API | 2,000-18,000 | 13.8-124.1 | 50-140 | 138 | 62.7 | 9875-49375 | 4483-22416 | 09875-4-000 |

| 9 7/8 | 250 | AP5 | 5.3.2 | 6 5/8″ API | 8,000 – 30,000 | 55.2-206.8 | 50-120 | 138 | 62.7 | 29625-59250 | 13450-26900 | 09875-5-000 |

| 9 7/8 | 250 | AP6 | 6.3.2 | 6 5/8″ API | 15,000 – 44,200 | 103.4-304.7 | 50-110 | 138 | 62.7 | 39500-69125 | 17933-31383 | 09875-6-000 |

| 9 7/8 | 250 | AP7 | 7.3.2 | 6 5/8″ API | 30,000 – 60,000 | 206.8-413.7 | 50-100 | 138 | 62.7 | 49375-79000 | 22416-35866 | 09875-7-000 |

| 10 5/8 | 270 | AP4 | 4.3.2 | 6 5/8″ API | 2,000-18,000 | 13.8-124.1 | 50-140 | 154 | 69.9 | 10625-53125 | 4824-24119 | 10625-4-000 |

| 10 5/8 | 270 | AP5 | 5.3.2 | 6 5/8″ API | 8,000 – 30,000 | 55.2-206.8 | 50-120 | 154 | 69.9 | 31875-63750 | 14471-28943 | 10625-5-000 |

| 10 5/8 | 270 | AP6 | 6.3.2 | 6 5/8″ API | 15,000 – 44,200 | 103.4-304.7 | 50-110 | 154 | 69.9 | 42500-74375 | 19295-33766 | 10625-6-000 |

| 10 5/8 | 270 | AP7 | 7.3.2 | 6 5/8″ API | 30,000 – 60,000 | 206.8-413.7 | 50-100 | 154 | 69.9 | 53125-85000 | 24119-38590 | 10625-7-000 |

| 11 | 279 | AP4 | 4.3.2 | 6 5/8″ API | 2,000-18,000 | 13.8-124.1 | 50-140 | 176 | 79.9 | 11000-55000 | 4994-24970 | 11000-4-000 |

| 11 | 279 | AP5 | 5.3.2 | 6 5/8″ API | 8,000 – 30,000 | 55.2-206.8 | 50-120 | 176 | 79.9 | 33000-66000 | 14982-29964 | 11000-5-000 |

| 11 | 279 | AP6 | 6.3.2 | 6 5/8″ API | 15,000 – 44,200 | 103.4-304.7 | 50-110 | 176 | 79.9 | 44000-77000 | 19976-34958 | 11000-6-000 |

| 11 | 279 | AP7 | 7.3.2 | 6 5/8″ API | 30,000 – 60,000 | 206.8-413.7 | 50-100 | 176 | 79.9 | 55000-88000 | 24970-39952 | 11000-7-000 |

| 12 1/4 | 311 | AP4 | 4.3.2 | 6 5/8″ API | 2,000-18,000 | 13.8-124.1 | 50-140 | 222 | 100.8 | 12250-61250 | 5562-27808 | 12250-4-000 |

| 12 1/4 | 311 | AP5 | 5.3.2 | 6 5/8″ API | 8,000 – 30,000 | 55.2-206.8 | 50-120 | 222 | 100.8 | 36750-73500 | 16685-33369 | 12250-5-000 |

| 12 1/4 | 311 | AP6 | 6.3.2 | 6 5/8″ API | 15,000 – 44,200 | 103.4-304.7 | 50-110 | 222 | 100.8 | 49000-85750 | 22246-38931 | 12250-6-000 |

| 12 1/4 | 311 | AP7 | 7.3.2 | 6 5/8″ API | 30,000 – 60,000 | 206.8-413.7 | 50-100 | 222 | 100.8 | 61250-98000 | 27808-44492 | 12250-7-000 |

| 13 3/4 | 350 | AP4 | 4.3.2 | 6 5/8″ API | 2,000-18,000 | 13.8-124.1 | 50-140 | 308 | 139.8 | 13750-68750 | 6243-31213 | 13750-4-000 |

| 13 3/4 | 350 | AP5 | 5.3.2 | 6 5/8″ API | 8,000 – 30,000 | 55.2-206.8 | 50-120 | 308 | 139.8 | 41250-82500 | 18728-37455 | 13750-5-000 |

| 13 3/4 | 350 | AP6 | 6.3.2 | 6 5/8″ API | 15,000 – 44,200 | 103.4-304.7 | 50-110 | 308 | 139.8 | 55000-96250 | 24970-43698 | 13750-6-000 |

| 13 3/4 | 350 | AP7 | 7.3.2 | 6 5/8″ API | 30,000 – 60,000 | 206.8-413.7 | 50-100 | 308 | 139.8 | 68750-110000 | 31213-49940 | 13750-7-000 |

| 15 | 381 | AP4 | 4.3.2 | 6 5/8″ API | 2,000-18,000 | 13.8-124.1 | 50-140 | 350 | 158.9 | 15000-75000 | 6810-34050 | 15000-4-000 |

| 15 | 381 | AP5 | 5.3.2 | 6 5/8″ API | 8,000 – 30,000 | 55.2-206.8 | 50-120 | 350 | 158.9 | 45000-90000 | 20430-40860 | 15000-5-000 |

| 15 | 381 | AP6 | 6.3.2 | 6 5/8″ API | 15,000 – 44,200 | 103.4-304.7 | 50-110 | 350 | 158.9 | 60000-105000 | 27240-47670 | 15000-6-000 |

| 15 | 381 | AP7 | 7.3.2 | 6 5/8″ API | 30,000 – 60,000 | 206.8-413.7 | 50-100 | 350 | 158.9 | 75000-120000 | 34050-54480 | 15000-7-000 |

| 16 | 406 | AP4 | 4.3.2 | 6 5/8″ API | 2,000-18,000 | 13.8-124.1 | 50-140 | 375 | 170.3 | 16000-80000 | 7264-36320 | 16000-4-000 |

| 16 | 406 | AP5 | 5.3.2 | 6 5/8″ API | 8,000 – 30,000 | 55.2-206.8 | 50-120 | 375 | 170.3 | 48000-96000 | 21792-43584 | 16000-5-000 |

| 16 | 406 | AP6 | 6.3.2 | 6 5/8″ API | 15,000 – 44,200 | 103.4-304.7 | 50-110 | 375 | 170.3 | 64000-112000 | 29056-50848 | 16000-6-000 |

| 16 | 406 | AP7 | 7.3.2 | 6 5/8″ API | 30,000 – 60,000 | 206.8-413.7 | 50-100 | 375 | 170.3 | 80000-128000 | 36320-58112 | 16000-7-000 |

Please use this chart as a guideline as drilling conditions will vary from site to site and Rock UCS (Unconfined Compressive Strength) is only one factor that contributes to “drillability” of any rock.

Other factors strongly influencing drillability are: fracture toughness, shear strength, young’s modulus of elasticity, Poisson’s ratio of stress vs strain, internal angle of friction. Rock variables must be considered when attempting to determine the best bit for overall life at optimum penetration rates. Other equally important factors affecting drilling performance are specific to the drilling equipment and operator. Notable items include: Driller experience and training, Compressor size and condition, Mechanical condition of the drill, pipe size and straightness, stabilizer size and condition, deck bushing size and condition, surface condition and overburden, sub surface blast fracturing, angle drilling, revolutions per minutes utilized, weight applied to bit, hole cleaning, water applied for dust control, lubrication provided for bit bearings, etc.

Mincon Envirosafe Tri-Lube is specifically formulated for blasthole drilling using rotary drills. Envirosafe Tri-Lube is an environmentally safe, high lubricity, water soluble lubricant, designed to extend the life of air bearing roller stabilizers, drill steel and rotary three-cone drill bits. It is injected into the air or water line at a rate of 1.5 liters (3 US Pints) per hour. Envirosafe Tri-Lube reduces downhole torque allowing joints to be broken easier, thus extending the life of the drill steel. It also reduces bit retipping by transferring heat from the cones and lubricating the cutting edge. Envirosafe Tri-Lube prevents corrosion of tanks and lubricates injection pumps, seals and hoses.