For this project full excavation of the area was not possible, so sheet piling activities must be carries out on all the foundations. As a sheet piling contractor, the first thing we ask for when a customer requests an offer is of course the geotechnical investigation report. This helps us not only to understand what type of sheet piles and machinery to use but also to optimize the offer in favour of the customer.

After signing the contract, we arrived on the jobsite with 2 teams and machinery and realized that the soil wasn’t as described in the geotechnical report, but much harder. After informing our customer, the General Contractor, we decided together to move on anyway and not to enter into a contractual claim with the beneficiary. This involved heavier machinery, more time and more cost.

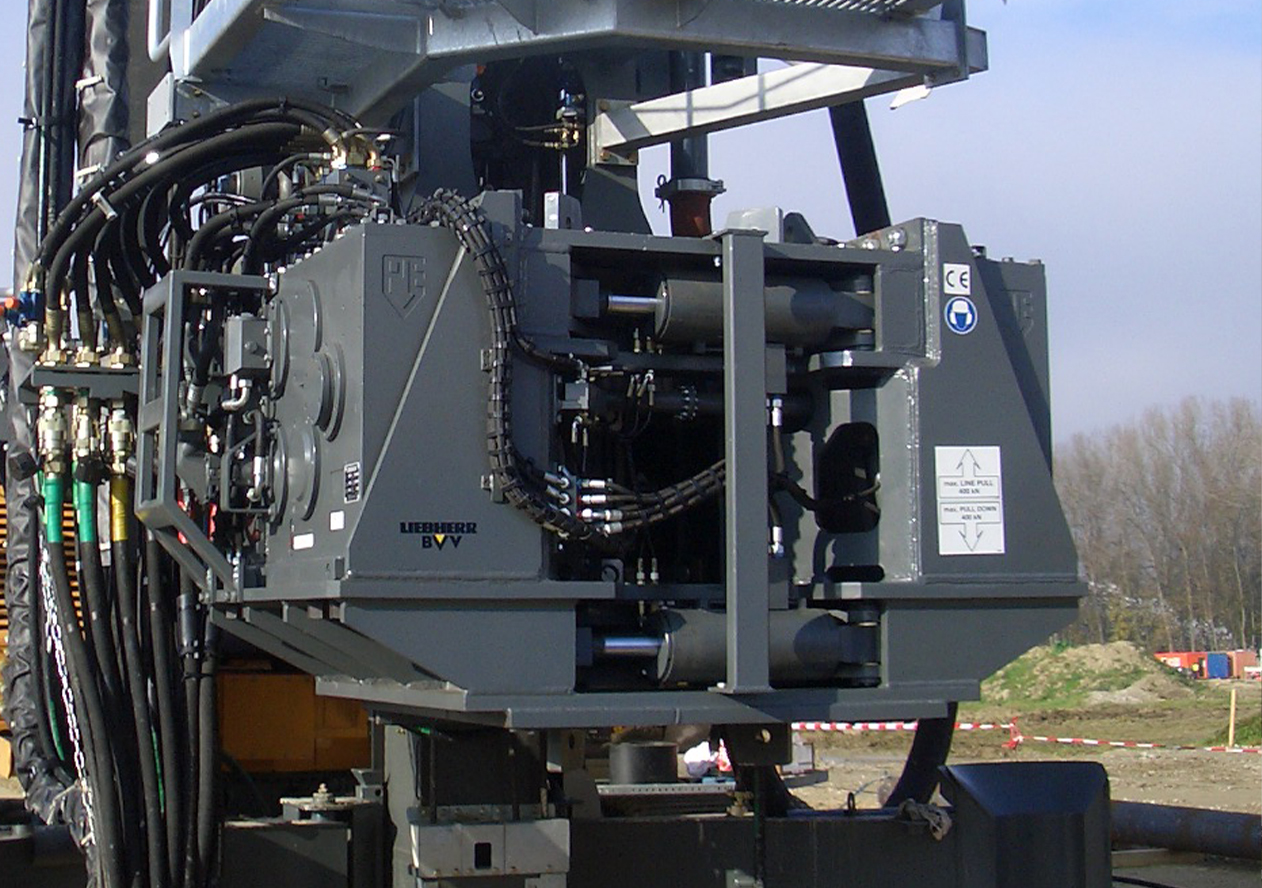

On the jobsite we had 2 crawler cranes, 100t/each, 1 telescopic crane, 2 vibro hammers – DIESEKO ICE 815C (used for installing) and ICE 416 (used for extracting), 2 teams of 4 people each.

Due to the ground conditions, at a certain point, a component of the 815C vibro hammer was not working anymore and we couldn’t continue the job.

The schedule was tight and the cranes standing still were generating a huge additional cost. At that time we learned how important is to have a strong and reliable machinery partner. We called our DIESEKO partner in Romania – RomNed and we explained the situation. It was Friday. Friday evening we got in the car with the representative of RomNed and arrived at the jobsite to fix the machine.

Unfortunately, the component couldn’t be fixed and had to be also calibrated by a Dieseko Specialist. On Sunday, a Dieseko specialist took a flight from the Netherlands to Romania and together with RomNed specialized personnel came at our jobsite with the new component and fixed the problem.

On Monday we were ready to work thanks to the support of our partners.

Source: dewateringandpiling.com