Timber Grapples with HPXdrive for Crane

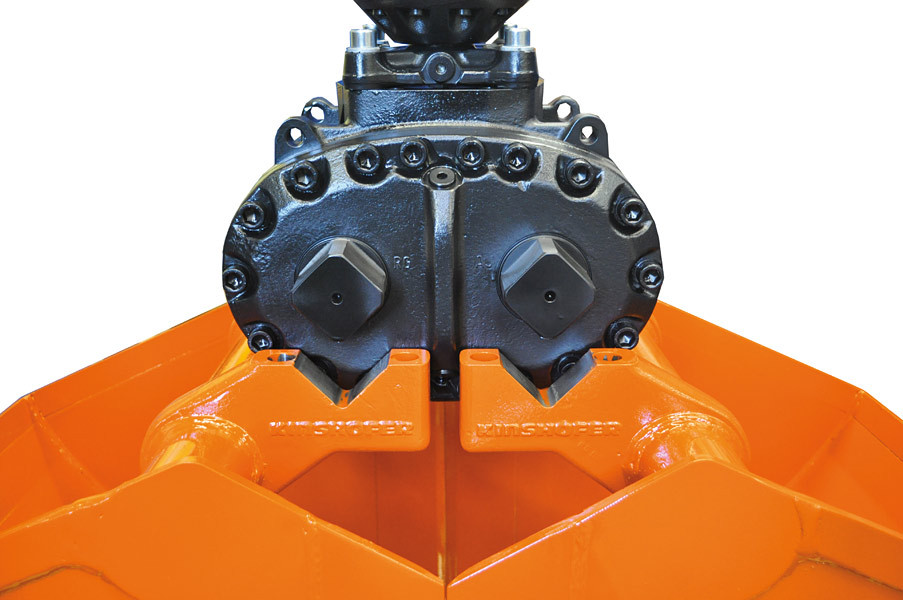

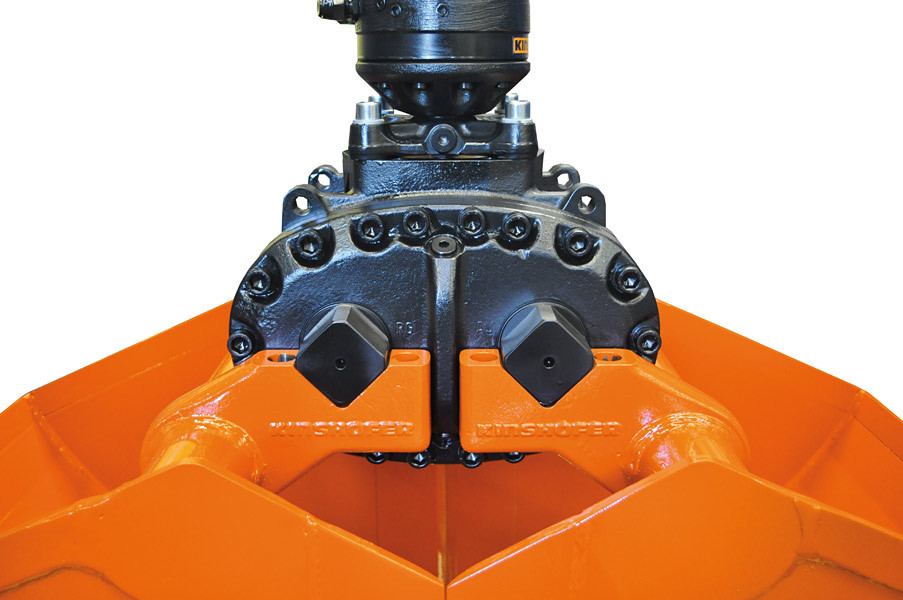

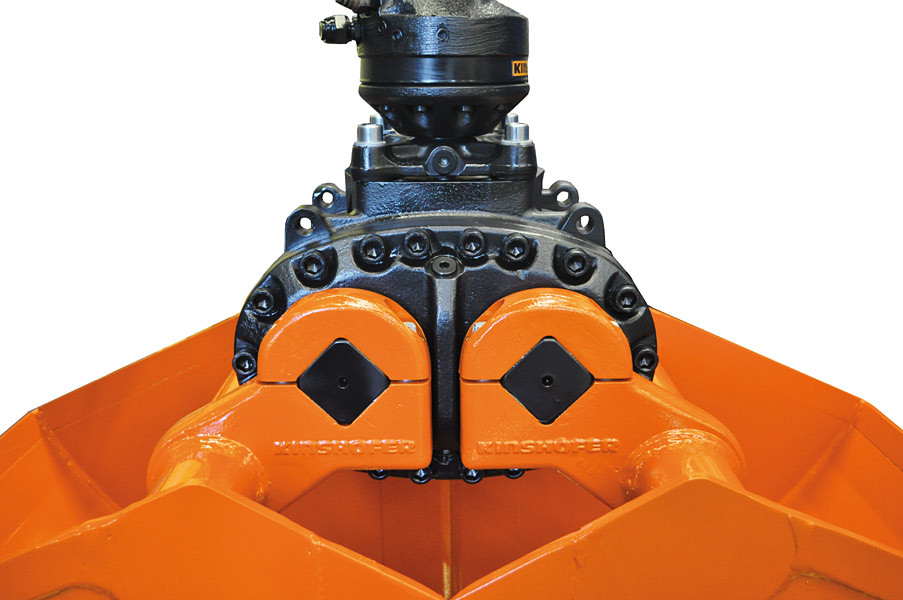

The reliability of the revolutionary HPXdrive in combination with robust, versatile tines – ideal for handling short logs, shrubbery, branches etc. Thanks to the drive system, the movement and closing force of the shells is constant and synchronized, generated by two hollow shafts, which run opposed and have a helix thread, hydraulically driven by a single piston.

The HPXdrive is available as standard or heavy duty version.

But no matter the size: There a no hydraulic cylinders required anymore!

A longer life cycle of up to 50% and the integrated self-lubrication as the drive unit runs in a permanent oil bath are also featured by the drive, as well as the compact design, making the HPXdrive resistant to dirt and debris.

Versatility is granted by different types of available shells that can easily be refitted onto the unit.

The perfect alternative to cylinder-operated grapples that do not only save time and cost, but also facilitate every task.

The timber grapples with HPXdrive are available as daily routine or heavy duty version, each featuring the respective HPXdrive.

The special US-logging grapple with HPXdrive Heavy Duty features a different style of shells and a stronger rotator.

A wide range of accessories, including different mounting options or load hooks are available for all timber grapples with HPXdrive.

KM 632HPX available in capacity 0,16 m² / 0.11 cords as complete ready-to-fit package: timber gapple, HPXdrive Standard, flange rotator, upper suspension, non-return and pressure relief valves.

KM 632HPX-HD available in capacity 0,16 m² / 0.11 cords as complete ready-to-fit package: timber gapple, HPXdrive Heavy Duty, flange rotator, upper suspension, non-return valve.

Special US-Version:

KM 632L HPX-HD available in capacities 0.25, 0.33 or 0.40 cords as complete ready-to-fit package: logging gapple, HPXdrive Heavy Duty, stronger flange rotator, upper suspension, non-return valve.

All HPX-packages are also available with shaft rotator and reduction link or quick change system.